ProLine Adaptive Series Welder

Engineers designed the ProLine Adaptive Series welder with two goals in mind: Create a versatile, precision machine with a small footprint to help maximize weld cell efficiency.

ProLine Adaptive Series BrochureThe result was the perfect modular pedestal welder, with fast and easy reconfiguration, within a compact unit that uses less than half the floor space of competitive flexible welders.

The ProLine Adaptive Series (PAS) welder’s capabilities are ideal for high-changeover applications in manual or robotic weld cells. The modular design, with over 1,000 base configurations, makes the PAS welder suitable for nearly any project, while reducing tool variation at the same time.

The plug-and-play system comes with a variety of transformers and weld controls to meet the needs and specifications of any project, assembled in one complete solution to save integration time and costs.

Why is this welder upside-down?

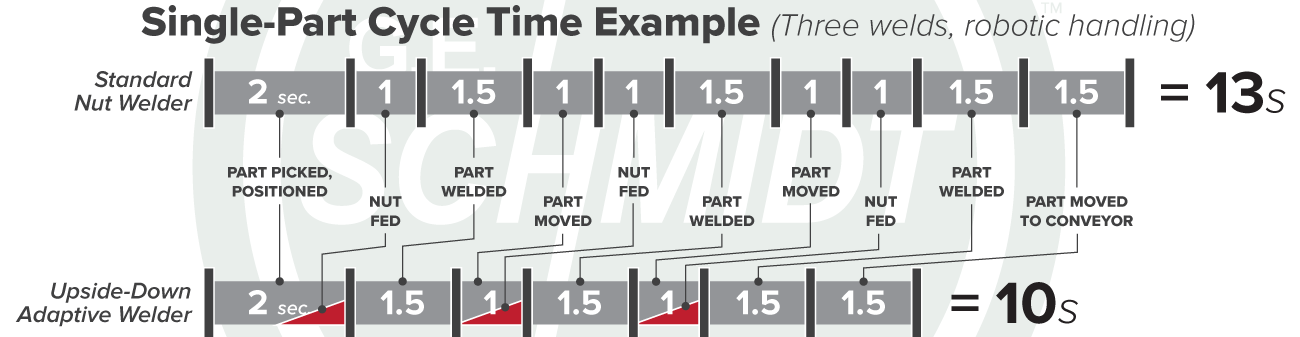

Positioning the cylinder on the bottom allows for concurrent stamping movement and nut feeding in robotic nut welding systems. Instead of requiring sequential operation — first position the stamping over the weld pin, and then feed the nut — stamping movement and nut feeding occur simultaneously. An upside-down welder may save as much as 1 second per weld in some applications. See the diagram below for an example of a part production timeline:

Though this is shown upside-down, the single frame can be converted on the floor to five configurations:

• Cylinder on Top, Pedestal Mount

• Cylinder on Bottom, Pedestal Mount (shown)

• Cylinder on Top, Bench Mount

• Cylinder on Bottom, Bench Mount

• Side or Back Mount

Big Performance

Modular Design — The PAS is available with three modular lower tooling setups available, including horn mounts, platen mounts and a quick change tooling mount. The PAS can evolve as projects change.

Fast Adjustments — Change the throat height. Change the lower tooling system. The PAS can adjust to meet the needs of most projects, and quickly. Operators can even adjust the height of the welder from shift to shift with an optional foot pedal, keeping the weld plane at an ergonomic level.

Milled Mounting Surfaces — The milled upper frame is designed to hold accessories true to the weld plane, whether engineers attach feeders or safety systems. The pre-tapped holes allow incremental adjustments without labor-intensive work.

ProLine Nut Verification System Compatible — The Adaptive Series features a mount for the ProLine Nut Verification System G-Series (NVS sold separately) at eye level to make inline quality control easy.

Small Footprint — The ProLine Adaptive Series makes the most of its space on the floor. Its footprint, 500 sq. in. (0.323 m2), is less than half the size of competitive modular welders, making the PAS welder perfectly suited for use in weld cells and nut farms.

Contact us today for more information on the variation and precision of the Adaptive Series welder and how it can take your project to the next level of productivity and efficiency.